“

To help to create a more sustainable future for our planet, we commit to

RE-DUCE the use of plastics,

RE-USE the plastics we already have.

But as the use of plastics cannot be completely avoided

RECYCLING is a third option to reduce the use of new raw materials.

And this is where we come in…

“

Let’s talk about waste

Our business starts with your plastic waste that you sort at home and throw in the PMD bag! Plastic packaging such as bottles, containers, trays, pots, dishes, bags and film (the ‘P’ in PMD) is collected from your home, sorted and separated into different material streams.

When leaving the sorting centre, the sorted plastic packaging is pressed into large bales to facilitate transport to the recycling plant. There, the packaging goes through several stages. They are washed, crushed and transformed into pure and ready-to-use pellets (flakes) or granules (pellets). These are purchased by Govaplast they are a valuable raw material.

Selection of raw material

Our production process starts with the selection of high-grade raw materials enabling us to produce high-quality products. The raw material consists of 100 % plastic recycled material (HDPE, LDPE and PP in a specific proportion). This material is purchased in Western Europe in the shape of a grind, agglomerate or re-granulate. Our buyer selects the most suitable suppliers based on quality and purity. We use PE and PP material that we transform into boards and posts, which are the basis of our entire product range.

PE = polyethylene

We know LDPE (low density PE) mainly as films, as outer packaging for water or soft drinks or bags for compost and bark.

Besides PE-films, films made of other materials also come onto the market, including PP (polypropylene). They are used to package products such as pasta, rice, sweets and biscuits.

The harder HDPE (high density PE) packaging for milk, detergent or shower gel is also mainly recycled and used as raw material.

PP = polypropylene

Then there is packaging made of PP including packaging for fabric softener, ready-made meals and butter dishes. . But also buckets and crates.

In short, if you see one of our benches in the park, there is a chance that it contains fractions of your own household waste!

Thought out production process

The PE-PP raw material is now mixed with dye and other additives to improve and strengthen the product. This typical Govaplast blend is melted into a homogenous mass under high temperature and sprayed into moulds. These moulds are cooled down, after which the boards are automatically pushed out. The final profiles can be sawn to size after 48 hours. The boards can be recycled after use.

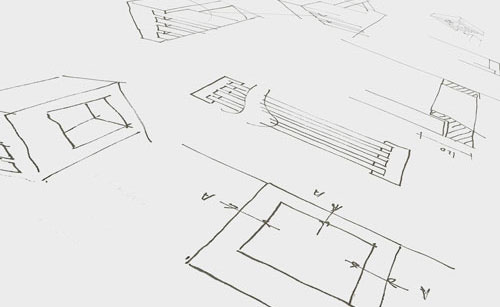

Design Experts

Govaplast always aims to be at the forefront of innovation when it comes to product development , design and manufacturing processes. We are constantly looking to meet our customer’s needs and to adapt our products to the latest requirements. Our street furniture range is a visible and clear example of how we invest in updating our business. We are cooperating with a fine selection of product designers to keep our eyes open to the world.

Quality tests and certifications

Our material has been tested by independent specialists with good results, emphasizing the confidence in our quality. This confidence is translated into a 10 year guarantee on the profiles. Test results and certificates are available and summarized in our technical product data.

Moreover, Govaplast is REACH compliant (read more on the regulations https://environment.ec.europa.eu/topics/chemicals/reach-regulation_en)

Govaplast has also a BQA QA-CER Recycled Content. This guarantees our quality system with regard to the recycling process and the use of recyclate, both in terms of the recyclate content and in terms of the quality of the end product. With the aim of supporting the sustainability principle. (read more on QA-CER on https://www.bqa.be/en/bqa-qa-cer-recycled-content)

“BQA QA-CER Recycled Content is one of the six European recognized control systems to certify companies in their declaration to the use of recycled materials. This certification offers an answer to an increasingly strict European regulation on plastic packaging.”

Wim Grymonprez – Manager New Business Developments Plastics & Lead Auditor

Service

Since its founding in 1995, Govaplast has always aimed at providing good service. Our motivated team takes care that your orders are being handled correctly and that your questions are being answered competently. We feel very strongly about flexibility and professionalism.

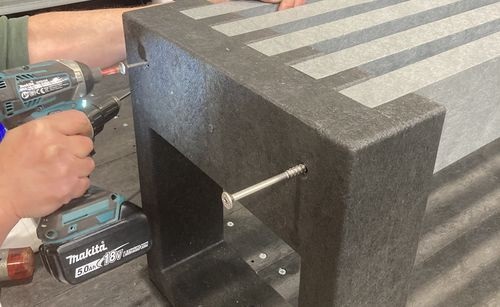

Assembly

The boards produced in our own facilities are also used in the manufacturing of our own street furniture and playground equipment ranges. In our assembly hall, an experienced team of craftsmen takes care of the precise assembly and high-quality finishing of the Street and Play collections.